Textile production is much more than just spinning cotton into denim or sewing fabric together. There’s a complex world of hidden, lesser-known segments that most brands miss. Ignoring these areas can mean missing opportunities for innovation, differentiation, and cost savings. This article explores these hidden corners of the textile ecosystem from technical textiles to non-woven innovations and why they matter for today’s brands and manufacturers—especially as highlighted in evolving apparel manufacturing trends shaping the future of fashion production.

What Is Textile Production?

Textile production transforms raw fibers natural, synthetic, or recycled into yarns, fabrics, and finished products for clothing, home textiles, and industrial use. It covers spinning, weaving or knitting, processing, dyeing, printing, finishing, and assembling across a wide range of textile and apparel products.

Clothtech: The Hidden Element Within Clothing

Clothtech includes textile components in clothing and footwear that aren’t visible, such as threads, interlinings, labels, zippers, elastics, and shoelaces. Often overlooked, clothtech is a critical functional part of technical textiles.

Why Clothtech Matters

- Enhances clothing performance and durability

- Provides functional properties like elasticity, insulation, and flexibility

- Often ignored in supply chain discussions

Brands that understand clothtech can boost both product performance and cost efficiency—an important factor when learning how to choose the right apparel manufacturer for your clothing brand.

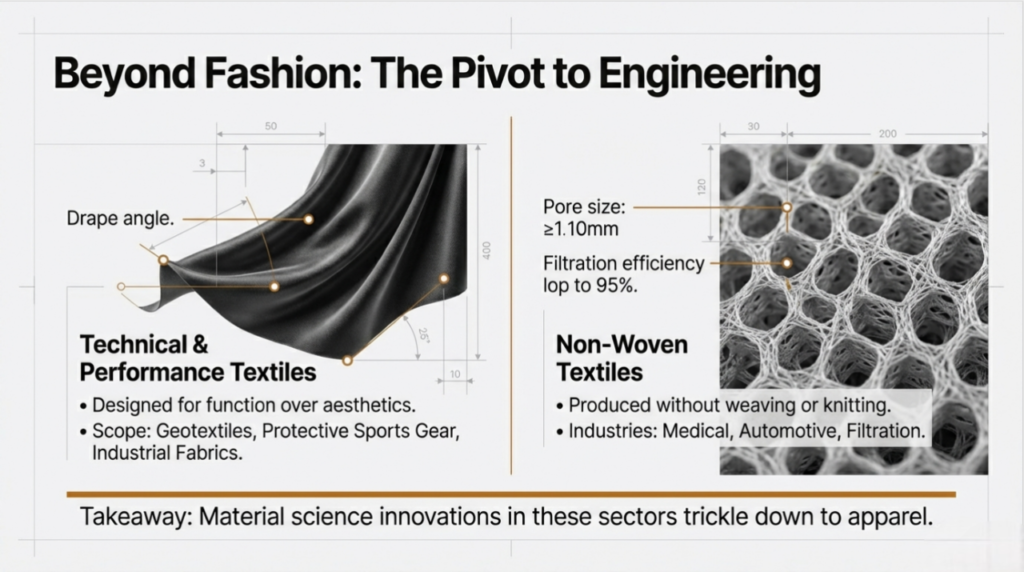

Non-Woven Textiles – Production Without Weaving or Knitting

Non-woven textiles are made by bonding fibers with heat, pressure, or adhesives, instead of weaving or knitting. They are used in filtration, hygiene products, construction, and specialized industrial applications.

Key Characteristics

- Faster production with less waste

- Recyclable

- Strong performance in medical, automotive, and filtration markets

- Produced by manufacturers serving niche, high-demand markets

Brands exploring non-woven textiles can expand their product lines with high-margin functional materials.

Technical & Smart Textiles; Performance First

Technical textiles are designed for specific applications, such as automotive seating or geotextiles in construction. Smart textiles, a growing category, may feature sensors, wearable tech, or materials that respond to stimuli.

These fast-growing segments often require expert guidance, which is why many brands turn to manufacturing advisory services to succeed in complex textile markets.

Examples of Technical Textile Sub-Segments

- Automotive textiles: seat fabrics, airbags

- Medical textiles: surgical gowns, wound care products

- Geotextiles: civil engineering materials

- Sportech and protectech fabrics: sportswear and protective gear

Tailored Fiber Placement & Specialty Techniques

Tailored Fiber Placement (TFP) allows precise placement of fibers for composite parts, especially in aerospace, automotive, and structural applications.

Recycled and Sustainable Materials

While sustainability is a hot topic, many brands overlook segments like recycled wool, regenerated fibers, and closed-loop systems that transform textile waste into new products.

Custom and Bespoke Manufacturing

Globalization has pushed many manufacturers toward mass production, but a growing niche focuses on bespoke manufacturing for small brands, designers, and specialized markets.

Behind the Fabric; The Supply Chain Ecosystem

Many brands are unaware of the hidden upstream sub-segments in textile production, including fiber producers, specialty dyers, and sustainable process innovators.

Conclusion

While the industry conversation often revolves around denim and apparel, a sophisticated world of hidden textile segments from clothtech to non-woven and smart textiles remains untapped. Understanding these areas opens doors to innovation, smarter sourcing, and a competitive edge.

FAQs (Voice Search Friendly)

Q1: What is textile manufacturing?

A: The process of transforming raw fibers into yarns and fabrics, then into finished products like clothing, home textiles, and industrial materials.

Q2: Who is a textile manufacturer?

A: A company or facility that converts fibers into yarn, fabrics, and finished products, covering spinning, weaving, and finishing processes.

Q3: What are non-woven textile manufacturers?

A: Companies producing textiles without traditional weaving or knitting, commonly used in medical, industrial, and hygiene applications.

Q4: Why are technical textiles important?

A: They provide performance features such as strength, durability, and resistance, ideal for automotive, medical, and industrial uses.

Q5: What is custom textile manufacturing?

A: Small-batch, specialized production tailored to unique designs, patterns, or performance requirements.

Add comment